Smart Cage Systems for Broiler Chicken: Optimizing High-Density Production

Broiler Industry: Vertical Farming Technology

The broiler industry is the most scaled sector in livestock farming. Developing vertical farming models(cage system for broiler chicken)—aimed at land conservation, feed efficiency, energy savings, high productivity, and ecological sustainability—integrates intensive production, digital intelligence, precision nutrition, biosecurity, and circular green technologies. This advancement is crucial for enhancing China’s broiler production capacity, market competitiveness, and building an efficient, resource-saving, environmentally friendly modern industry.

By optimizing vertical farming equipment, this model increases land output per unit area. Digitalized environmental control systems improve rearing conditions. Integrated feeding management, feed-saving techniques, and disease prevention enhance bird health and performance. Manure collection and recycling technologies enable crop-livestock integration and emission reduction.

Compared to traditional flat-net systems, vertical farms house 30,000–60,000 birds/barn (vs. 10,000–20,000) and enable one worker to manage up to 100,000 birds. Currently adopted by >70% of white-feathered broiler farms, the model shows vast potential for yellow-feathered and small white broilers.

I. Farming Process

(1) Scale & Density

- All-in/all-out single-phase system

- Barn capacity: 30,000–60,000 birds; farm capacity: 300,000–500,000 birds

- Space: ≥0.05 m²/bird (<20 birds/m²)

- Reduce density during high temperatures

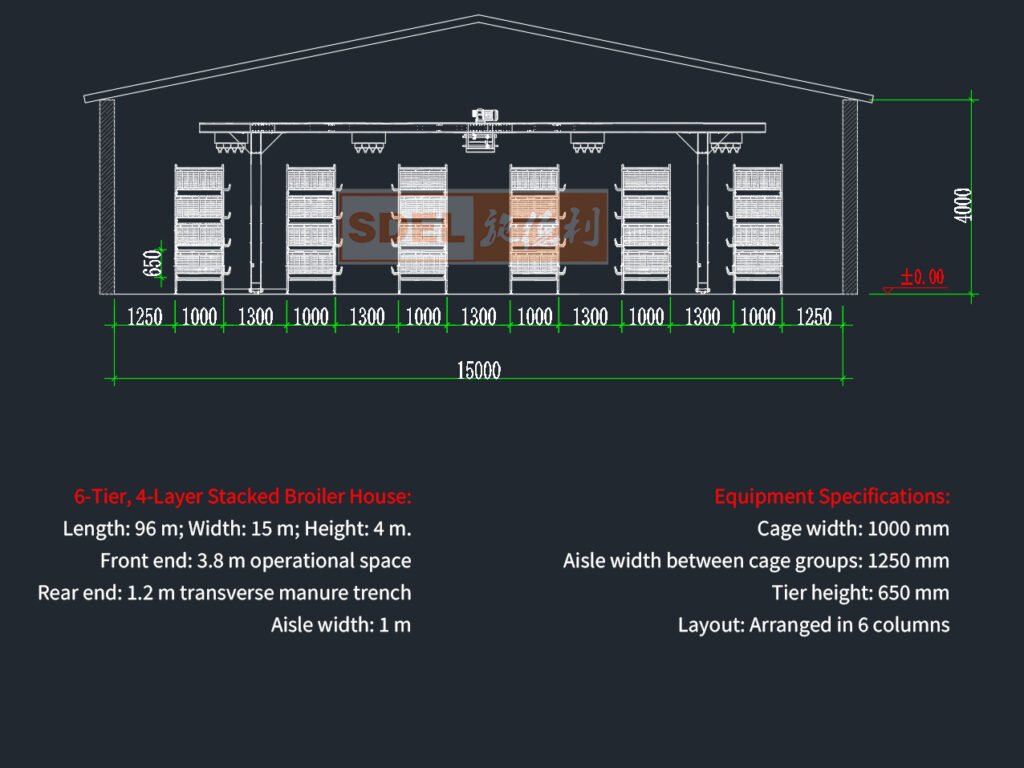

(2) Layout & Cages

- Barn design: Enclosed, insulated structures (80–90m L × 15–18m W)

- Cages: 3–5 tier galvanized systems (15+ year lifespan)

- Layout specs:

- Aisles: 0.9–1.5m between rows

- Ventilation channels: 0.35–0.5m between columns

- Cage dimensions: 0.7–0.9m W × 1.1–1.4m L

(3) Equipment

- Feeding systems:

- Automated rail feeders with emergency stops

- Adjustable funnels to reduce waste/dust

- Feed troughs adaptable to bird size

- Silos storing >2 days’ feed (e.g., ≥15 tons for 50k birds)

- Water systems:

- NY5027-compliant water quality

- Components: Filters, medicators, 360° nipples, regulators

- Height-adjustable lines

- Manure systems:

- Conveyor belts (PP material, anti-static/aging)

- Layered clearance → transverse belt → external transport

- Frequency: From once/2 days to 2–4 times/day

- Overhead nets prevent bird contact

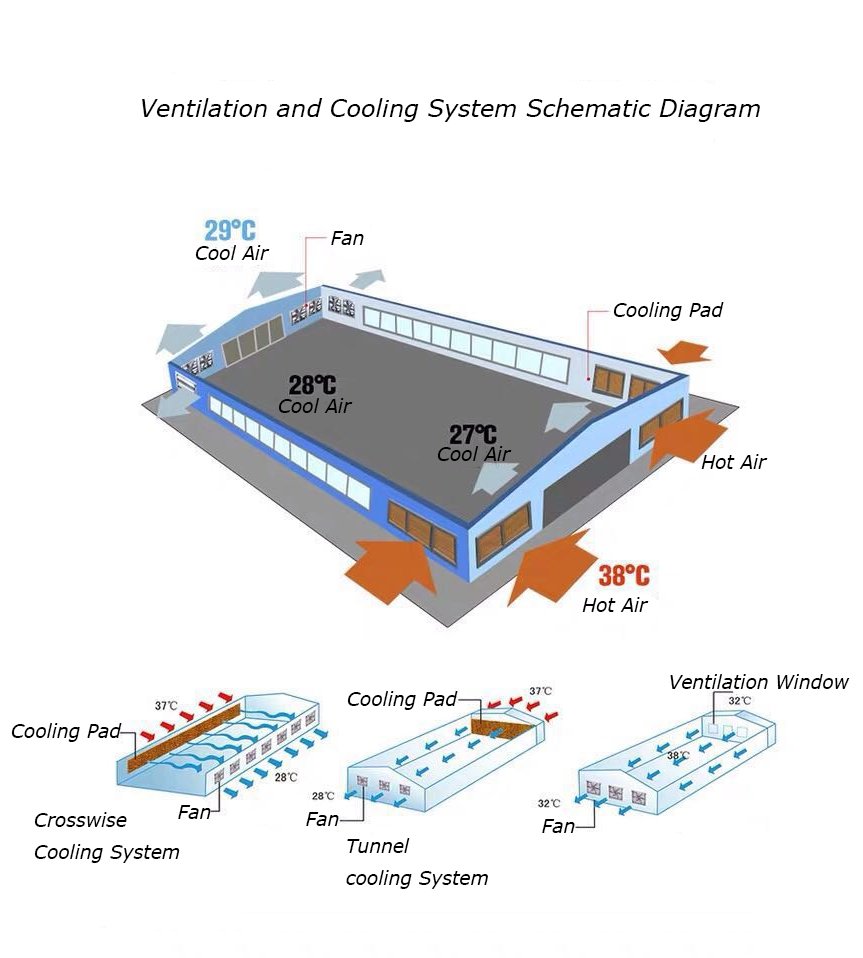

II. Environmental Control

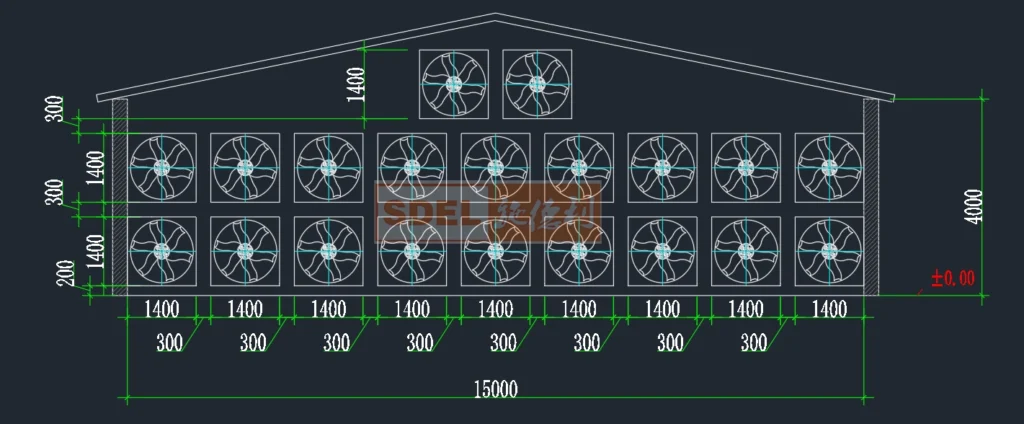

(1) Equipment

- Ventilation: Tunnel fans with air cones (Fig.4), side inlets (30×60cm)

- Cooling: Graded evaporative pads

- Heating: Floor heating/heaters + solar thermal recovery

- Controllers: Automated adjustment of inlets/curtains/fans

(2) Automated Management

- Sensors monitor: Temp (24.2–33.8°C), RH (45–60%), NH₃ (<10ppm), CO₂ (<3500ppm)

- Max temp variation: <3°C

- O₂ maintained ≥19.5% via staged ventilation

| Parameter | Standard |

|---|---|

| O₂ | ≥19.5% |

| CO₂ | ≤3500 ppm |

| NH₃ | ≤10 ppm |

| H₂S | ≤0.5 ppm |

| PM2.5 | ≤800 μg/m³ |

III. Feed & Nutrition

- Phase feeding:

- 3-stage: Starter (1–14d), Grower (15–28d), Finisher (29d-market)

- 4-stage (optimal): Starter (1–9d), Grower I (10–20d), Grower II (21–29d), Finisher (30d-market)

- Efficiency: NSP enzymes ↑ nutrient utilization ↓ emissions

IV. Digital Management

(1) IoT Production

- Real-time monitoring: Feed/water, environment, gas levels

- Automated control via 4G/5G/NB-IoT

(2) Information Systems

- Cloud-based analytics for multi-site tracking

- AI-driven anomaly alerts

(3) Traceability

- Full-chain tracking: Feed → medication → slaughter → sales

- QR code access to health records

V. Biosecurity

(1) Farm Zoning

- NY/T 388《Environmental Quality Standard for Livestock and Poultry Farms》(china)-compliant planning

- Strict separation: Living/production/waste zones (Fig.7)

- All-in/all-out per barn

(2) Protocols

- Disinfection: Personnel/vehicle/material sanitation

- Pest control: Rodent/bird/insect exclusion

- Vaccination: Hatchery-based or aerosol delivery

- Robotic inspection: Autonomous health monitoring

The cage system for broiler chickens stands at the core of vertical farming’s transformative impact, enabling unprecedented efficiency through three pillars:Space Revolution,Precision Control,Data-Driven Sustainability。

Future Focus: Next-gen cage designs will prioritize modularity, AI-driven health analytics, and seamless integration with renewable energy—propelling broiler farming toward true autonomy.