H type battery cages or A type battery cages for chicken farm?Here’s your answer: Choose A-type for under 30,000 birds; go with H-type for 50,000+!But why?Please read on.

Lately, we’ve noticed that several layer farmers have been feeling a bit torn when it comes to choosing between H type battery cages and A type battery cages for poultry farming. It’s a common dilemma—both systems have their pros and cons, and deciding which one works best can be tricky.

So, based on years of hands-on experience, we’re here to break things down and help you make a smart, informed decision!

First off, let’s quickly introduce the two mainstream systems used in layer farming today: the H type battery cages and the A type battery cages. Both can be fully automated—think feeding, drinking, manure cleaning, egg collection, and climate control. They’re designed to reduce labor intensity and cut down on manual work. Pretty cool, right?

🐔 A type battery cages System

In this system, cages are arranged in an A-shape. Manure removal can be done using either a scraper or a belt system. It’s one of the earlier designs in layer farming and remains popular among small to medium-sized farms.

Pros:

- Great ventilation on every tier thanks to the open design—even in open-style houses.

- Excellent natural light exposure🌞, which means you can often rely more on daylight.

Cons:

- Occupies more floor space due to lower stocking density.

- Manure from upper tiers can drop onto chickens in lower cages… not ideal for hygiene.

🏢 H type battery cages System

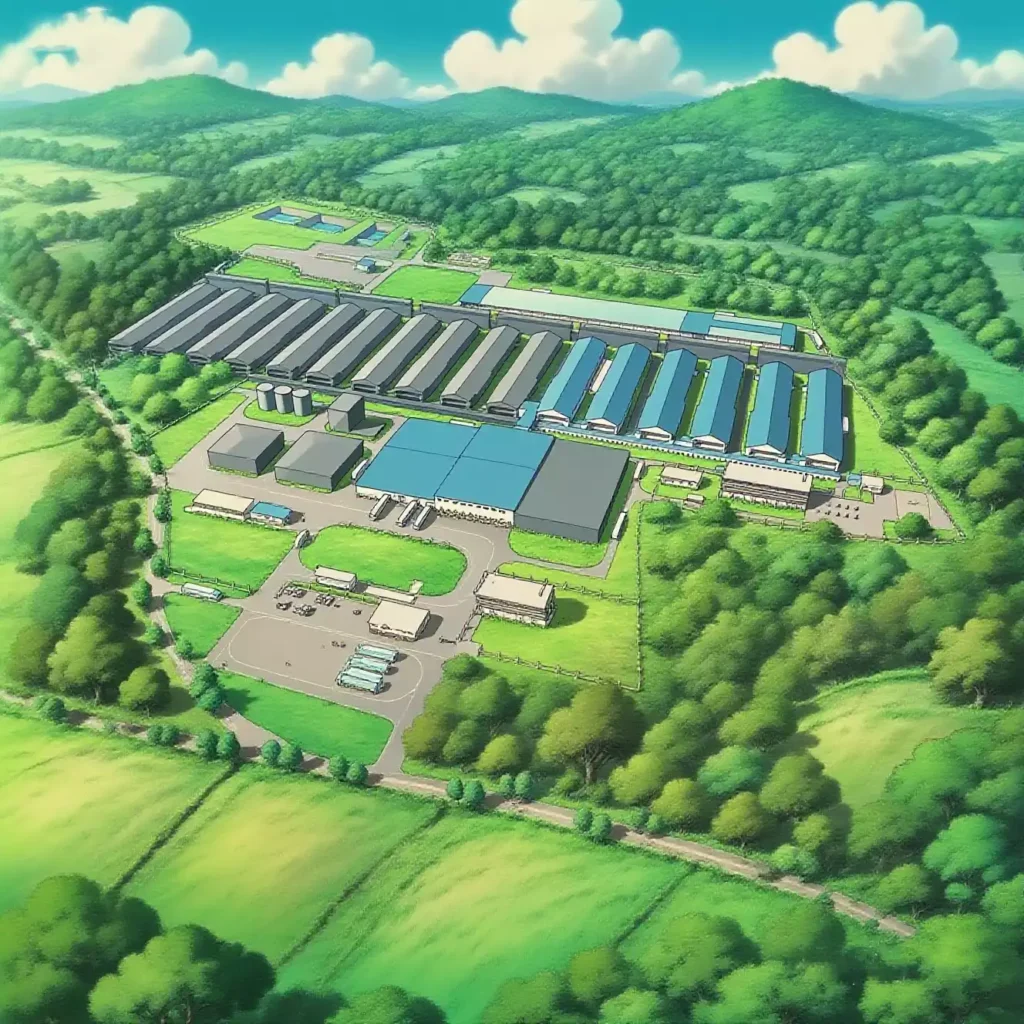

As the name suggests, cages are stacked layer upon layer—like a high-rise building! This system has gained popularity as land resources have become scarcer. To maximize space, farmers are going vertical—some even build up to 8–10 tiers, raising 100,000 birds in a single house!

Pros:

- Full automation📶—drastically reduces labor needs and raises efficiency.

- Each tier has its own manure belt, which keeps the environment cleaner and healthier.

- High space utilization—perfect for intensive and large-scale farming.

- Manure is removed layer by layer, making collection and reuse easier while reducing environmental impact.

- Fully enclosed system helps prevent diseases and improves overall flock performance.

Cons:

- Requires a closed-house setup with automatic temperature control—otherwise, climate management gets challenging.

- Higher risk and bigger initial investment. One house can easily contain tens of thousands of birds.

🤔 So… Which One Should You Choose?

Well, there’s no one-size-fits-all answer—it really depends on your situation.

If you’re running a farm with under 30,000 birds, the A type battery cages System might be a better fit—it’s simpler and still highly functional.

For those with 50,000 birds or more, the H type battery cages System will likely deliver better ROI and efficiency in the long run.

At the end of the day, it all comes down to your scale, budget, and vision.

We’d love to hear what you think! Have you used either system? What was your experience? contact us!