How to Choose Chicken Farm Cage for poultry farming

If you are considering investing in layer farming, it is essential to first understand the necessary chicken farm cage and poultry farming facilities. Successful egg production requires a comprehensive set of tools and infrastructure to ensure flock health, maximize laying efficiency, and reduce management costs. The main equipment and facilities include the following:

I. Infrastructure

- Poultry House

- Types: Open-sided (natural ventilation) or environmentally controlled (closed, ideal for large-scale farming).

- Requirements: Weatherproof (wind, rain), insulated, hardened floors (for easy cleaning and disinfection), well-designed ventilation inlets and drainage systems.

- Layout: Zoned management (e.g., brooding area, laying area, isolation area).

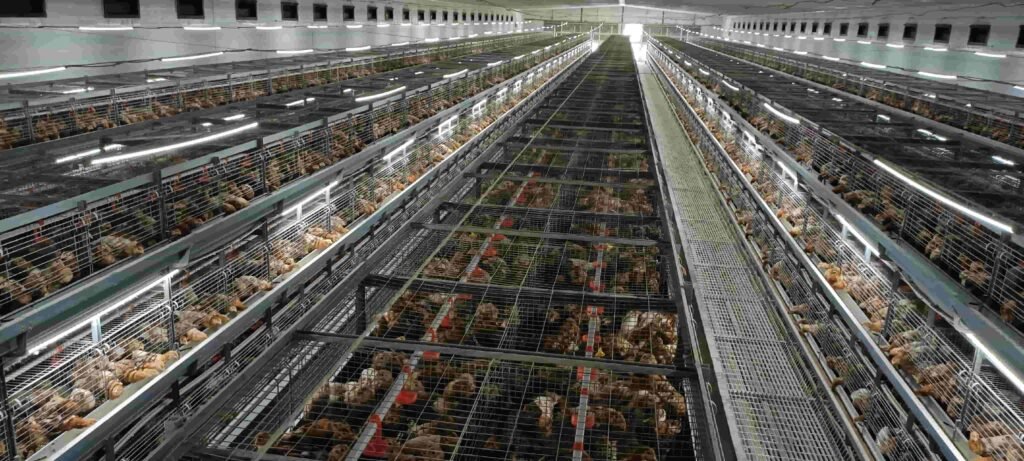

- Chicken Farm Cage Systems

- Battery Cages: Space-efficient, suitable for large-scale operations, facilitates automation; requires well-designed structure for bird activity, feeding, and management.

- A type Cages: Provides more uniform ventilation and light distribution, but occupies more space.

- Free-range Systems: Suitable for free-range or welfare farming; requires litter (e.g., wood shavings, rice hulls).

II. Poultry Farming Core Equipment

- Feeding Equipment

- Automated Feeding System: Includes feed bins, conveying pipes, and troughs for timed, quantitative dispensing.

- Standard Troughs/Feeders: Suitable for small-scale farming; requires manual feed replenishment.

- Drinking Equipment

- Nipple Drinkers: Water-saving, hygienic, reduces water contamination.

- Cup or Trough Drinkers: Lower cost, but require regular cleaning.

- Egg Collection Equipment

- Automated Egg Collection System: Conveyor belts transport eggs centrally to a handling room or egg storage, reducing breakage.

- Manual Collection: Requires egg trays, baskets, etc.

- Environmental Control Equipment

- Temperature Control: Heat lamps, hot air blowers (winter), pad-and-fan cooling systems (summer).

- Lighting System: LED lights with timers to simulate natural photoperiod (14-16 hours of light per day).

- Ventilation System: Exhaust fans, ventilation inlets to ensure air exchange and reduce ammonia concentration.

- Manure Handling Equipment

- Manure Scrapers: Automatically remove manure; often used with stair-step cages (traditional method).

- Manure Belts: Used in multi-tiered stacked cage systems to periodically remove manure from the house.

- Manure Treatment Equipment: e.g., compost fermenters, turning machines, to convert manure into organic fertilizer.

III. Auxiliary Equipment

- Disinfection Facilities

- Footbaths (house entrance), spray disinfectors, UV lamps.

- Monitoring Systems

- Temperature/humidity sensors, ammonia detectors, cameras (for remote flock monitoring).

- Weighing and Recording Tools

- Scales, production record sheets (to track lay rate, feed consumption, etc.).

IV. Disease Prevention and Control Equipment

- Vaccine Storage

- Refrigerator or freezer (for storing vaccines and medications).

- Vaccination Tools

- Syringes/droppers (for administering vaccines or medications).

- Isolation Cages

- For isolating sick birds to prevent disease spread.

- Carcass Disposal Equipment

- Incinerators or deep burial pits/bins (for safe disposal of dead birds).

V. Other Facilities

- Feed Storage Room

- Moisture-proof, rodent-proof, for storing feed ingredients or finished feed.

- Egg Storage Room

- Temperature-controlled (12-15°C), humidity-controlled (75-80% RH) environment to extend shelf life.

- Backup Power System

- Generator (essential for power outages, especially in closed houses).

- Transportation Tools

- Feed carts, egg transport crates, etc.