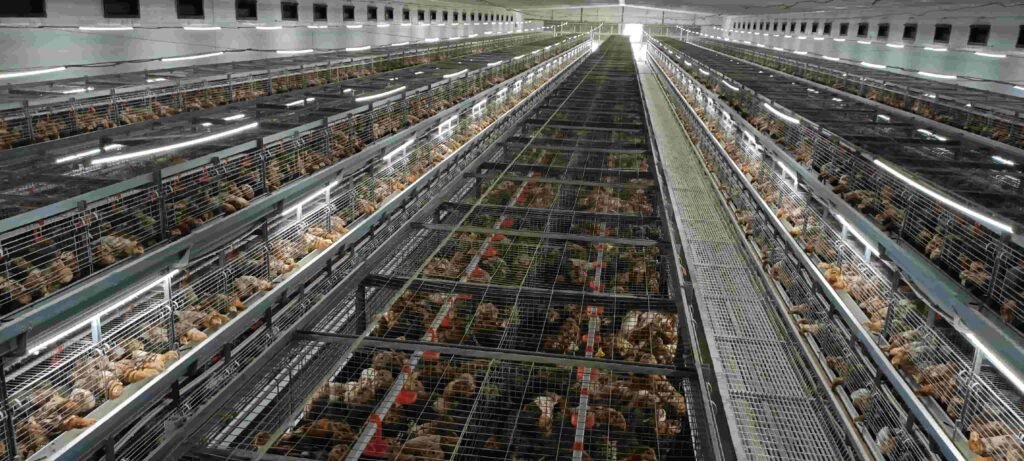

1-Million-Layer Automatic Poultry Farm

The land area required for a fully automatic poultry farm with 1 million egg-laying hens is influenced by the breeding model and the extent of automation. Here is a general analysis:

1. Core Production Area (Poultry Houses)

- Stocking Density: In a modern, automated stacked cage system, each bird typically requires 0.05–0.08㎡.

- Total House Area: For 10 automated houses, the total building area would be approximately 17,000 square meters (e.g., 10 houses * 1,700 ㎡).

- Land for Houses and Spacing: Including essential spacing between buildings for ventilation and biosecurity, the total land area dedicated to the poultry houses would be about 30,000 – 50,000 square meters.

2. Auxiliary Facility Area

- Automated Feed Storage & Silo Area: Designed for bulk deliveries and automated conveying systems, requiring ~3,000 – 5,000 square meters.

- Manure Treatment Area: Housing automated manure removal systems (e.g., conveyor belts) and processing equipment, needing ~5,000 – 8,000 square meters.

- Central Egg Collection & Packing Plant: A dedicated, automated facility for egg collection, grading, washing, and packaging, requiring significant space.

- Office, Control Room & Living Quarters: Includes the central farm control room for monitoring the automatic poultry farm systems, offices, and staff facilities, needing ~2,000 – 3,000 square meters.

- Disinfection & Biosecurity Buffer Zones: Critical in an automatic poultry farm, including vehicle wash bays and personnel entry facilities, requiring ~2,000 – 3,000 square meters.

- Utilities & Maintenance: Housing generators, electrical substations, and workshops for automated equipment, needing ~1,000–2,000 square meters.

3. Other Areas

- Space for internal roads, drainage, green belts, and potential future expansion requires ~20,000 – 30,000 square meters.

In summary, a modern automatic poultry farm of this scale requires approximately 60,000 – 100,000 square meters of land (90 – 150 Chinese acres). The actual area will depend on the specific layout and automation design.

The investment required is substantial, underscoring the capital-intensive nature of modern automatic poultry farming:

- Site Preparation & Infrastructure: Land leasing, leveling, and high-capacity utility installation: ~¥50 million.

- Construction: Building heavily automated poultry houses and core facilities: ~¥300 million.

- Automated Equipment: Integrated systems for feeding, drinking, climate control, manure removal, egg collection, and central monitoring: ~¥400 million.

- Pullets: Acquisition of 1 million young hens: ~¥300 million.

- Feed Costs: Feed from pullet arrival until the flock reaches peak production: ~¥450 million.

- Environmental Protection: Advanced waste treatment systems: ~¥100 million.

- Vaccination & Healthcare: ~¥50 million.

- Labor: While an automatic poultry farm reduces manpower, it requires skilled technicians and managers; annual costs are ~¥100 million.

The total initial investment can reach approximately ¥1.75 billion. Therefore, large-scale automatic poultry farming is a sector dominated by major capital. The high costs of land, automated infrastructure, and ongoing operational expenses like feed create significant barriers to entry for small-scale farmers.

The industry is seeing market consolidation. Success in this competitive automatic poultry farming landscape requires not only capital but also precise management of technology, resources, and market timing to achieve profitability.