Pullet Cage system

▼Add:Intersection of Lijiang Road and Wenchang Road in New Area, Hua County, Henan, China

✉Email:marketing@sdeley.com

▶Web:www.sdeley.cn

Automatic Layer Pullet Cage System,

Pullet Equipment for Chicks

SDELEY The automatic pullet cage system

The SDELEY Automatic pullet Cage System revolutionizes the rearing of 0-6 week-old pullets with its modular cage banks and precision environmental control. Engineered to bridge brooding and layering phases, this system ensures uniform growth through:

- Adjustable cage tiers (Can be customized)

- Gradual feeder height adaptation

- Soft-wire flooring

Smart Automation Features

Intelligent Feeding

Light Management

Temperature Control

- Health Monitoring

Why Choose SDELEY?

- 20% higher uniformity at transfer to layer cages

- 17% lower feed waste vs conventional systems

- Modular expansion (add other modular

The SDELEY system reduced our pullet mortality from 3.2% to 1.7%, with 92% reaching target weight at 16 weeks

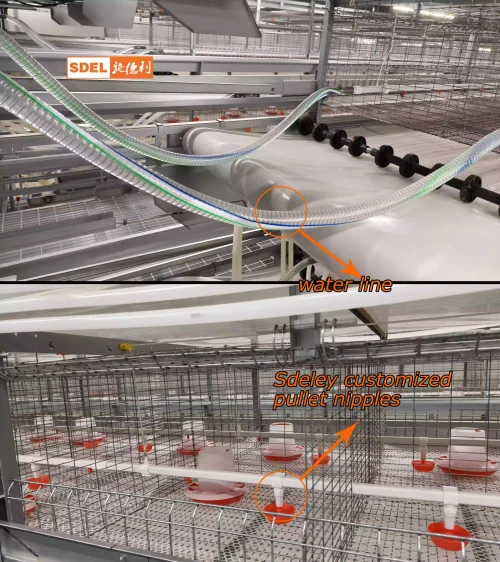

Water line dedicated square pipe, high-quality PVC material

Sdeley customized pullet nipples

Stack feeding machine and head and tail frame:the frame of the feed car is made of 275g galvanized steel plate,The motor reducer adopts top-tier Chinese motor brands。

Feed cart rail:3*5 hot-dip galvanized square pipe, wall thickness 2.0mm

Feed line: 110PVC screw conveyor, relay screw conveyor, South African screw conveyor

Feed tower: 51.4 cubic meters (33.4 tons)

Illumination system: 0%-100% adjustable light

Temperature control system;A precision environmental management system designed for growing pullets during the pre-laying phase, maintaining:

- Temperature range: 21-28°C (gradually adjusted weekly)

- Humidity control: 50-65% RH

Manure remover: The frame structure is made of 275g hot-dip galvanized steel sheet, thickness 3mm, equipped with a domestic first-line brand reducer motor, with a manure door and a secondary manure scraping device.

Transverse and oblique manure remover: Green high-quality PVC manure belt, thickness 3.0mm, oblique 9 meters.

Manure removal support frame: 275g hot-dip galvanized steel sheet, including a complete set of support frame accessories

Manure belt: Imported raw materials, PP material, thickness 1.2mm

GET IN TOUCH WITH US

We can ship our equipment to Philippines, Malaysia, Indonesia, Thailand, PNG, Africa, America, etc. Please feel free to Email us via the contact form below, we’ll get back to you as soon as possible.(24-48hours)

Note: The following options will help our sales improve their work efficiency, if you have no idea about them, just leave it blank.