Broiler Cage

▼Add:Intersection of Lijiang Road and Wenchang Road in New Area, Hua County, Henan, China

✉Email:marketing@sdeley.com

▶Web:www.sdeley.cn

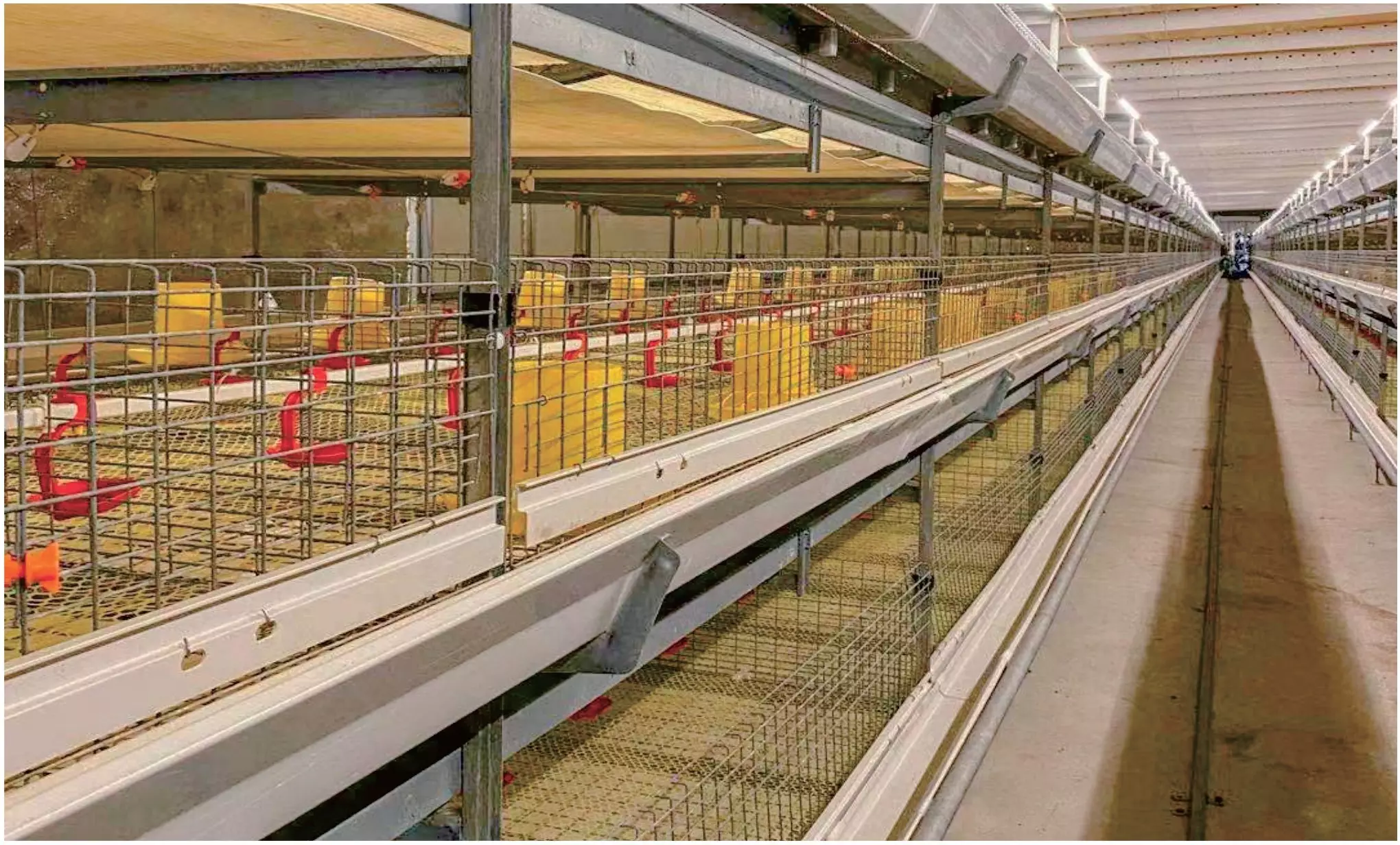

About Automated broiler Cage System

❶Efficient❷labor-saving❸disease-controlled❹high-yield❺feed-saving.

2.An intelligent vertical farming system designed for modern broiler farms, achieving standardized production with 42-day market weights of 3.0-3.5kg and FCR as low as 1.5:1 through precision environmental control, automated feeding management, and smart data analytics。

Broiler Cage Raising Equipment – Product Advantages

- Fully assembled, with high installation accuracy and easy maintenance.

- Adjustable drinking water system, allowing chickens to drink at a 45° angle at different growth stages.

- Feeding methods include overhead trolley and side bucket, both available for selection.

- The manure removal mechanism reduces the chance of the manure belt deviating and ensures thorough manure removal.

- Multiple environmental control designs with automatic emergency system switching to ensure property safety.

- Facilitates rapid and safe growth of broilers.

- The reasonable design of the back net partition effectively increases air circulation.

- The rear end adopts closed operation, reducing secondary pollution in the chicken house and environmentally friendly treatment of chicken manure inside the house.

The H Type broiler Cage System consists of several parts:

1.Cage Group System 2.Feeding System 3.Manure removal system 4.Ventilation and cooling system 5.Drinking water system 6.Lighting System 7.Electrical control system 8.Supporting system

Core design differences between broiler and layer cage systems:

| Comparison Dimension | Broiler Cage System | Layer Cage System |

|---|---|---|

| Production Goal | Rapid weight gain (40-45 days to market) | Long-term egg production (72-80 week cycle) |

| Stocking Density | 18-20 birds/m² (EU standard) | 12-15 birds/m² (enriched cage standard) |

| Cage Height | 30-40cm (restricts movement to promote growth) | 45-60cm (ensures natural standing behavior) |

| Floor Design | Plastic flat mesh (prevents breast blisters) | Sloped galvanized mesh (7-8° angle for egg rolling) |

While the design philosophies differ, the management systems share similarities (1. Cage Group System, 2. Feeding System, 3. Manure Removal System, 4. Ventilation and Cooling System, 5. Drinking Water System, 6. Lighting System, 7. Electrical Control System, 8. Supporting System), which can reference layer cage systems. The key distinctions lie in many specific technical parameters.

At the Nanle three-tier broiler cage project installation site, the client stocked chicks on Day 23 and completed acceptance inspection on Day 27.

At the Tai’an three-tier broiler cage renovation project installation site, the client stocked chicks on Day 24 and completed acceptance inspection on Day 28.

At the Cheng’an three-tier fully automated broiler cage installation site, the client stocked chicks on Day 25 and completed acceptance inspection on Day 29.

GET IN TOUCH WITH US

We can ship our equipment to Philippines, Malaysia, Indonesia, Thailand, PNG, Africa, America, etc. Please feel free to Email us via the contact form below, we’ll get back to you as soon as possible.(24-48hours)

Note: The following options will help our sales improve their work efficiency, if you have no idea about them, just leave it blank.