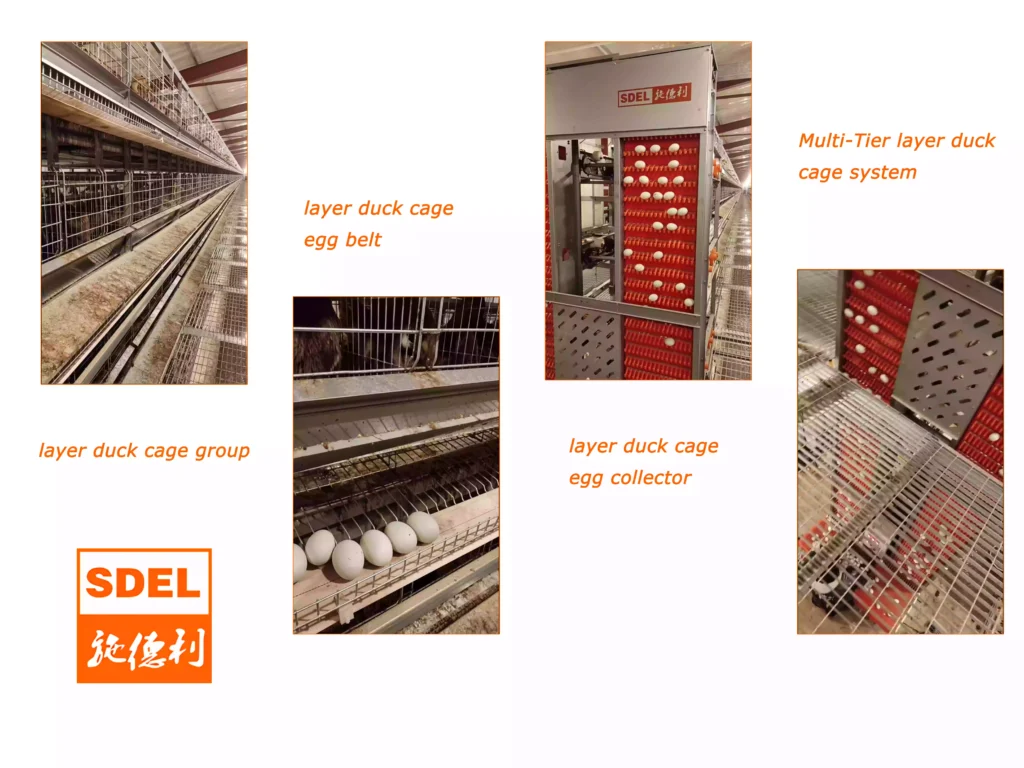

Layer Duck Cage System Technical Overview

Layer Duck Cage System Structural Design & Innovations

This tiered cage system features optimized spatial design with each duck occupying 780cm² floor area, grouped in 5-door modules (1300mm length × 600mm depth × 500mm height). The configuration houses 2 ducks per cage door – balancing stock density with behavioral needs while enabling vertical integration. The 500mm tier height exceeds industry minimums, accommodating natural standing/movement behaviors, while the 600mm depth minimizes feed waste during reaching. With galvanized steel construction and modular scalability, the system achieves 43% higher stocking density than flat-deck alternatives while reducing labor inputs by 55%.

1. Space & Efficiency Breakthrough

5-door modules (1300mm length) → Labor cost ↓50%

780cm²/duck → 45% space saving vs free-range

500mm height → Precision climate control (±1℃)

2. Core Benefits Realization

| Requirement | Solution |

|---|---|

| Spatial efficiency | 3-tier vertical density (45 ducks/m²) |

| Labor productivity | Central feeding/egg collection |

| Disease control | Isolated units + daily manure removal |

| Economic return | FCR 2.4:1 (vs 2.8:1) |

| Environmental protection | Sealed manure system → NH₃<15ppm |

3. Climate Control Standards

- Building Envelope: Polyurethane insulation (K≤0.4W/㎡·K)

- Ventilation Formula:

Airflow (m³/h) = Ducks × Weight(kg) × FactorSummer Factor: 7.5 Winter Factor: 1.8

- Golden Rule: Never compromise duck health for energy savings

4. Egg Quality Certification

| Parameter | Traditional | Cage System | Improvement |

|---|---|---|---|

| Dirty eggs | 15-30% | ≤2% | ↓90% |

| Breakage | 3-8% | 0.5% | ↓94% |

| Salmonella | >25% | <1% | ↓96% |